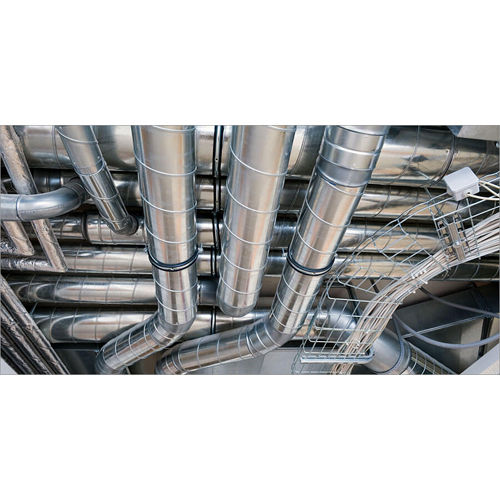

Sheet Metal Ducting Work

Sheet Metal Ducting Work Specification

- Insulation

- Optional (Acoustic / Thermal)

- Process

- Cutting, Bending, Welding, Riveting

- Surface Finish

- Galvanised/Zinc Coated

- Usage

- Air Handling & Distribution

- Application

- HVAC, Industrial Ventilation, Air Conditioning, Exhaust Systems

- Air Tightness Class

- Class A/B/C (as per standards)

- Maximum Length Per Section

- 2500 mm

- Connection Type

- Flanged & Gasketed / Slip-On

- Product Name

- Sheet Metal Ducting Work

- Color

- Metallic Silver (Standard)

- Material

- Galvanized Iron (GI) Sheet

- Shape

- Rectangular / Square / Circular

- Size

- Custom as per requirement

- Corrosion Resistance

- Yes

- Installation

- On-site fabrication & assembly

- Compliance Standards

- SMACNA / IS 655

- Thickness

- 0.6 mm - 1.2 mm (customizable)

About Sheet Metal Ducting Work

Spotlight your HVAC and industrial ventilation needs with our Featured Sheet Metal Ducting Work, available to Buy Online for unmatched convenience. Engineered from potent Galvanized Iron (GI) sheets, this invincible solution ensures sublime performance in air handling and distribution. Choose optional acoustic or thermal insulation to maximize efficiency. With flanged & gasketed or slip-on connections and compliance to SMACNA/IS 655 standards, our ducts offer superior corrosion resistance and air tightness (Class A/B/C). Customize thickness, shape, and size for seamless integration in air conditioning and exhaust systems. Metallic silver finish exudes both durability and style.

Competitive Advantages, Applications, and Users

Sheet Metal Ducting Work offers exceptional corrosion resistance and flexible installation options, enhanced by state-of-the-art galvanization and manufacturing techniques. Competitive advantages include invincible durability, tailored sizing, and compliance with global standards. Used extensively by HVAC contractors, industrial builders, and facility managers, the ducting serves as the backbone of air handling, ventilation, and exhaust systems in commercial, industrial, and institutional spaces. Clients trust this solution for potent air distribution, reliability, and enduring operational performance.

Payment Terms, Packaging, and Sample Availability

Experience streamlined logistics with prompt Estimate generation and secure Handover processes. Flexible payment terms are available to accommodate project needs. Each Sheet Metal Ducting section is robustly packed for safe national or international transit. Customized packaging supports damage-free delivery via trusted logistics partners. Samples can be requested to assess quality and fit prior to large-scale order commitment, ensuring buyer satisfaction and transparency at every step of the procurement journey.

Competitive Advantages, Applications, and Users

Sheet Metal Ducting Work offers exceptional corrosion resistance and flexible installation options, enhanced by state-of-the-art galvanization and manufacturing techniques. Competitive advantages include invincible durability, tailored sizing, and compliance with global standards. Used extensively by HVAC contractors, industrial builders, and facility managers, the ducting serves as the backbone of air handling, ventilation, and exhaust systems in commercial, industrial, and institutional spaces. Clients trust this solution for potent air distribution, reliability, and enduring operational performance.

Payment Terms, Packaging, and Sample Availability

Experience streamlined logistics with prompt Estimate generation and secure Handover processes. Flexible payment terms are available to accommodate project needs. Each Sheet Metal Ducting section is robustly packed for safe national or international transit. Customized packaging supports damage-free delivery via trusted logistics partners. Samples can be requested to assess quality and fit prior to large-scale order commitment, ensuring buyer satisfaction and transparency at every step of the procurement journey.

FAQ's of Sheet Metal Ducting Work:

Q: How is the Sheet Metal Ducting Work customized to my specific project requirements?

A: The ducting is fully customizable in thickness, size, length (up to 2500 mm per section), and shape (rectangular, square, or circular). Our team works closely with you to tailor every specification to your air handling and distribution needs.Q: What insulation options are available for this ducting?

A: You have the option to include acoustic or thermal insulation, based on your project's requirements. Both options enhance energy efficiency and sound attenuation in air handling systems.Q: Where is this Sheet Metal Ducting Work typically used?

A: These ducts are widely used in HVAC installations, industrial ventilation, air conditioning, and exhaust systems for commercial, industrial, and institutional facilities.Q: What is the process for ordering and installation?

A: After you request a quote or place an order online, a detailed estimate is provided. Ducts are fabricated, packed, and delivered to your site where our technicians carry out on-site assembly and installation according to SMACNA and IS 655 standards.Q: What are the key benefits of choosing this ducting solution?

A: Key benefits include potent corrosion resistance, sublime air tightness, compliance with international standards, versatile design, and invincible reliability for long-lasting air distribution performance.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free